Process Overview

Adopting the latest Technology for Efficient and Reliable Manufacturing

It is a process of making parts by pouring molten metal into a die and then cooling it to room temperature so that it takes the shape of the die. It is a less expensive method of manufacturing compared to machining an entire piece of solid metal. Casting is broadly categorized into three main types :

This process is characterized by using sand as the mold material. The mold cavities and gate system are created by compacting the sand around patterns which can be made of wood, metal, plastics, silicon rubber etc. and manufactured by casting, machining or 3D printing based on the requirement of the final casted part.

The mold is formed by dipping or spraying ceramic slurry around a wax pattern or wax tree. Prior to pouring, the wax is burnt off by keeping it in a steam-dewax autoclave or flash fire oven. On completion, the same is cooled to room temperature and the shell is removed usually by mechanical tools. The parts are then machined, ground and polished to achieve the required dimensions and characteristics. The general process flow for Investment Casting include :

- Wax Pattern Injection

- Wax Tree Assembly

- Shell Building

- Dewax/Burnout

- Metal Pouring

- Shell Knock-off

- Cut-off

- Individual Casting

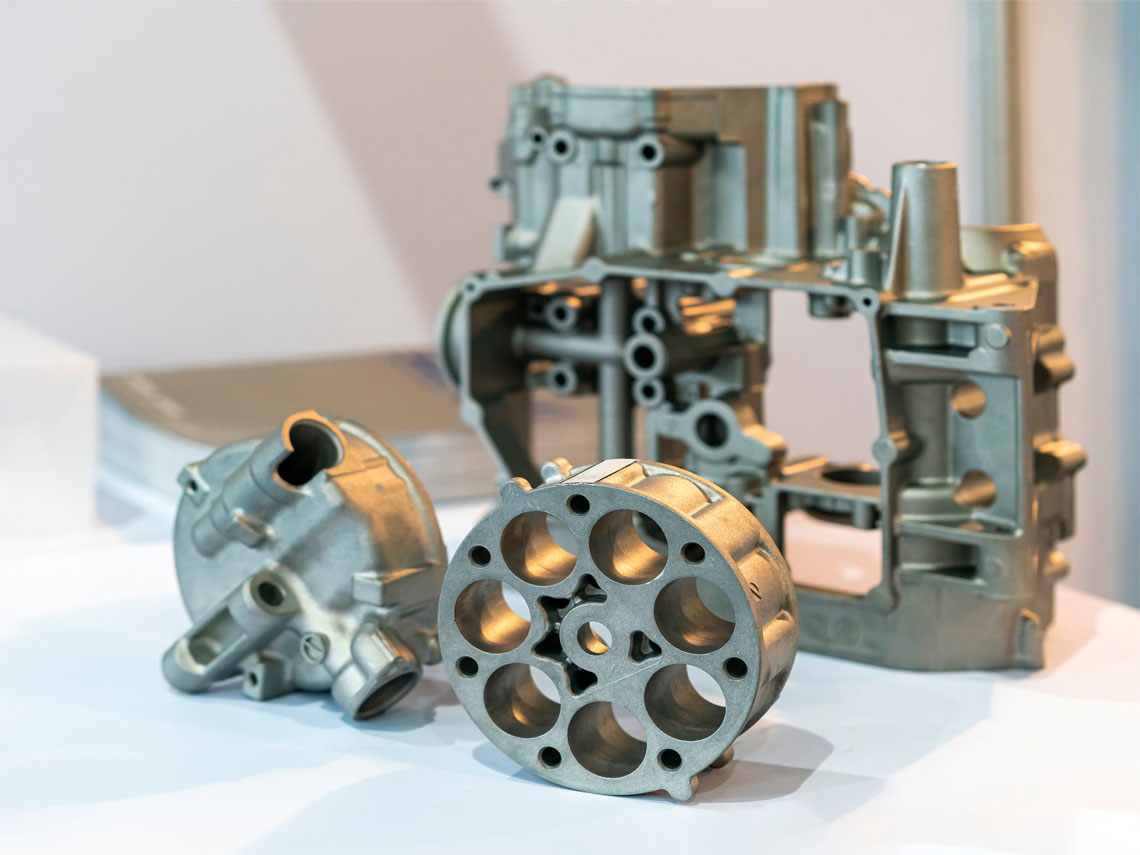

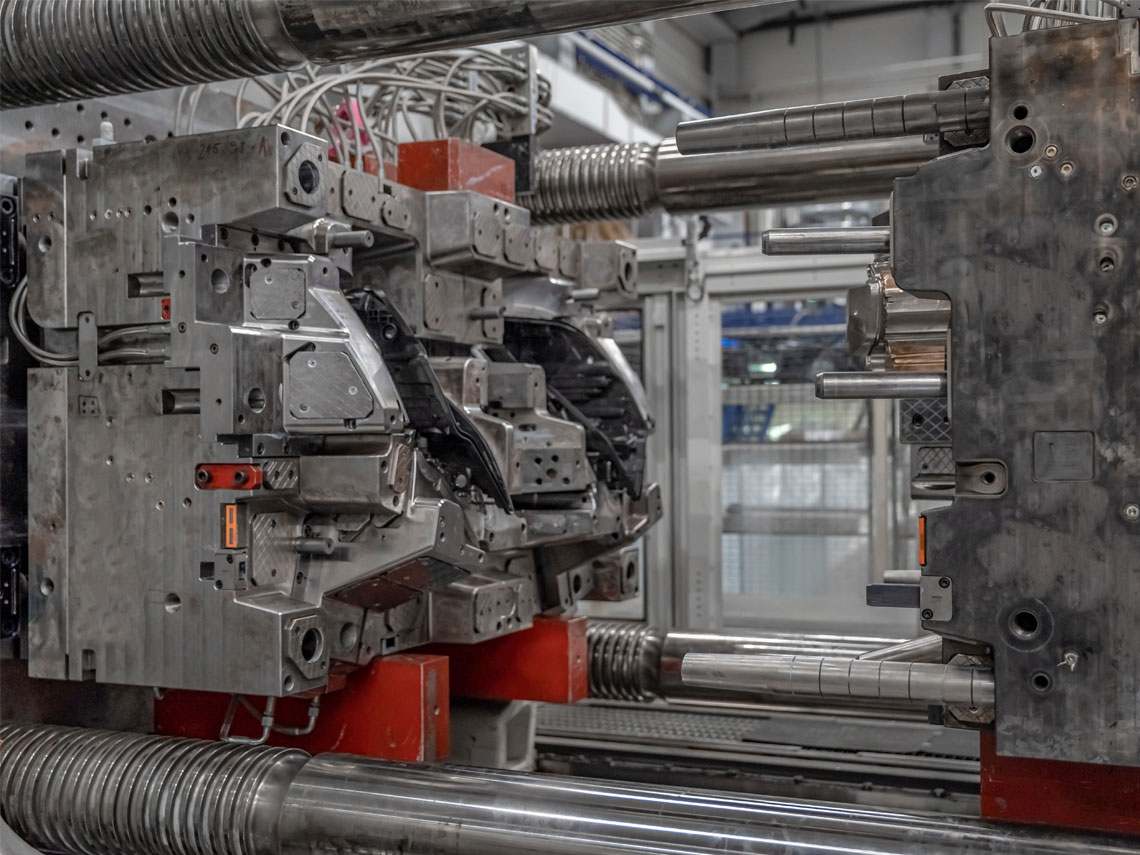

The molten metal is forced into a mold cavity made up of metal, under the application of high pressure or under gravity. In Gravity Die casting the molten metal gets drawn into the mold under the action of its own gravity. Pressure Die casting is further classified into Low, Medium, and High-pressure basis the force exerted by the plunger to push the molten metal inside the mold cavity. Pressure Die castings have a tight tolerance, better surface finish, high volume production and very critical parts compared to its contemporary casting processes. A die cast part has to go through the below process flow :

- Melting

- Casting

- Fettling

- Shot Blasting

- Machining

Materials

Commodities that we emulsify into Finished product

We manufacture almost any alloy with sand casting due to its ability to cast materials with high melting temperatures. Casted parts may be heat treated to achieve the desired mechanical and chemical properties. Sand casted parts are vacuum impregnated to make them impregnable and increase its overall integrity. Parts may also be surface treated for enhancement of physical properties and visual appearance. We can cast Ternary, Quaternary, Quinary and Sextary Superalloys by investment casting. Die castings are mainly used for manufacturing of non-ferrous alloys. Few of the common materials we cast are as follows :

Alluminium Alloys

Magnesium Alloys

Brass Alloys

Zinc Alloys

Copper Alloys

Cast Iron Alloys

Low Alloy Steels

High Alloy Steels

Tool Steels

Nickel and Cobalt based Alloys

Capabilities

A synopsis of our Skills and Expertise

- Integrated sequential manufacturing process under one roof i.e., Simulation -> Tool designing and manufacturing -> Prototype -> Manufacturing

- Prototype to high volume production of up to million parts per year

- Monthly production capacity of up to 100MT/month

- Capability to cast parts up to 10 Tonnes

- Manufacturing of wide variety of grades such as Carbon Steel, Stainless Steel, Duplex, Super Duplex, Aluminum and Brass Alloys etc.

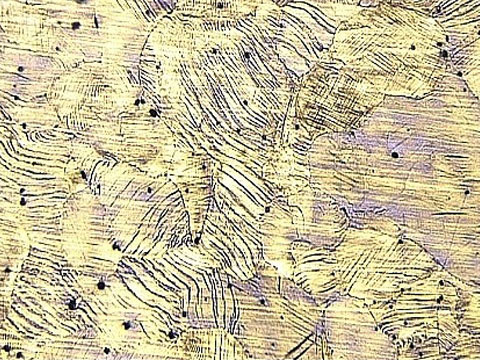

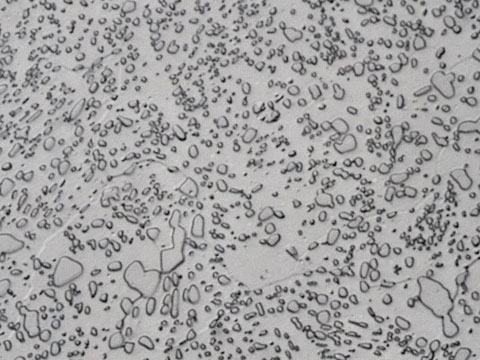

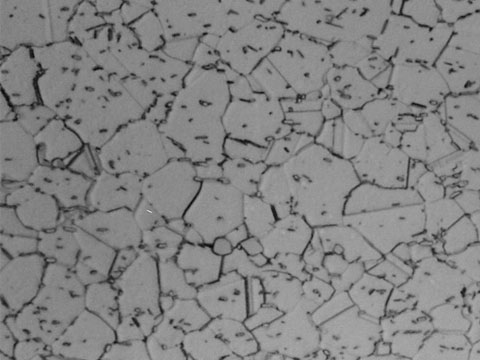

- Different follow up Heat Treatment process such as Normalizing, Annealing, Hardening, Tempering etc. based on the requirement of mechanical and chemical properties

- Post finishing and surface treatment process such as Anodizing, Painting, Plating, Powder coating etc.

- Flexibility of end-to-end machining of small to large sized parts

- Achieve as cast tolerance of up to ± 0.2mm and machined tolerance of up to ± 0.025mm

- As cast surface finish as low as 1.6 Ra micron

- Use of advanced CAD-CAM software for simulation and tool/die making

- One of the few in INDIA to perform Hot Isostatic Process (HIPPING)

- Use of "Low Therm Fettling Technique" to control microstructure

- In-house lab tests carried out for raw material verification at production site, certified to NABL standards

- Complete NDT testing of parts for defect analysis as per international standards

- Manufacturing facility certified to ISO 9001:2015 and IATF 16949 Quality Management System

Application and Benefits

Gain an Advantage over your Competition

- Sand castings have a wide range of application in almost all engineering industry due to its versatility of material selection, simplistic process, and low cost. Few common applications in the Transport and Automotive industry include cylinder heads, valves, engine blocks, engine manifolds, gears, brackets etc.

- Sand castings are primarily chosen for manufacturing of prototype parts due to its low investment cost and higher degree of flexibility

-

Investment casting is widely used for :

- Engineering components such as turbines and rotor blades in motors and generators

- Valve parts such as casings, pistons etc.

- Wide variety of Orthopedic implants

- Commercial and Consumer products

- Many die cast parts are made in the Aerospace and Automotive industry from high strength aluminum and light weight magnesium

-

Few well known benefits of Die casting include :

- Manufacturing of critical parts with cross section as thin as 1.5mm

- Manufacturing of parts with complex geometry and diverse applications

- Parts have better strength and integrity

- High volume production

- Fully automated process with better process control

- Better repeatability gives consistent good quality parts

- Parts have high dimensional accuracy, close tolerance, surface finish and longer service life

- Post-machining can be eliminated

- Molds have a very long operational life

- Very economical for high volume production

Frequently Asked Questions

Got Questions? We’ve Got Answers!

- Yes, sand casting being a very raw and inexpensive process is commonly used for prototyping. The cost of making die and mold is much cheaper compared to other forms of casting process.

- As sand castings are more susceptible to inherent defects and lower throughput, they can’t be directly considered as a reflection of final product in case of mass production.

-

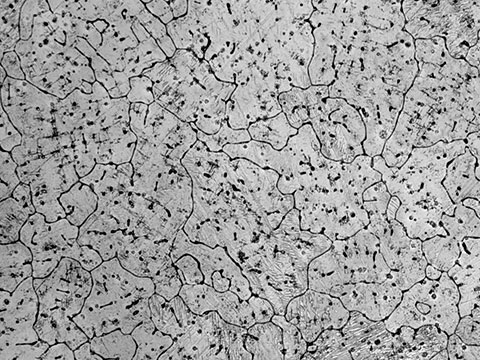

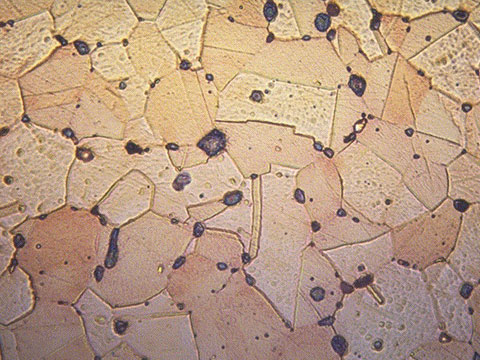

Due to complexities in the investment casting process, numerous defects can be observed such as :

- Inclusions – Presence of foreign particles

- Hot tear – When there is restriction to shrinkage of molten metal by ceramic shell mold during cooling

- Misrun – When molten metal is unable to fill mold cavity completely

- Cold shut – When two metal streams do not fuse together properly in the mold cavity

- Runout – When molten metal leaks out of mold while pouring

- Shrinkage – It occurs when there is a change is casting section

- Wax damage – When the wax pattern has been mishandled

- Bulge – Wax patterns too close resulting in ceramic shell bridging

-

Pros

- High dimensional accuracy

- Require minimum machining

- Lower restriction on part size

- Make parts with lower wall thickness

- Automated process with shorter lead times

-

Cons

- High tooling cost

- Can’t be used for ferrous alloys

- Suitable only for mass production

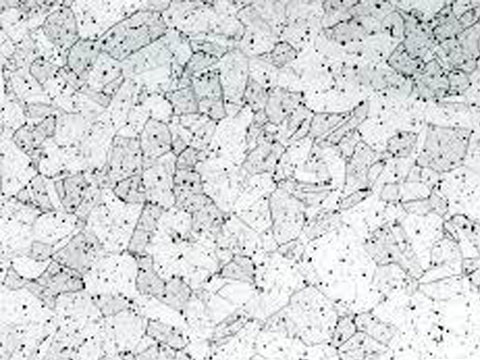

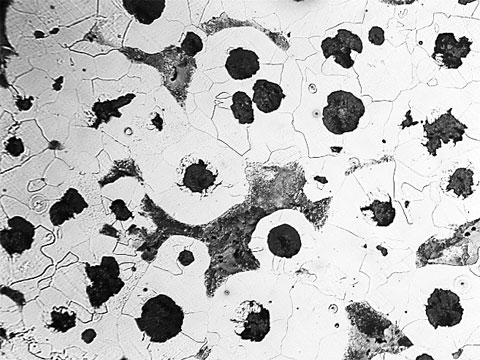

- Gas porosities – Due to gas entrapment

- Drags – Damage on the surface of die cavity and insufficient hardness

- Cracks – High Fe element. Low die temperature. Non uniform wall thickness

- Deformation – Poor casting structural design

- Sinks – Injection pressure too low. Uneven wall thickness of the casting

- Short filling – Poor fluidity of molten metal. Low injection pressure

- Flashes – Injection speed too high. Clamping force of die is insufficient

- We have developed and keep upgrading our capabilities by adding professional and experienced vetted suppliers to our vendor network. Please refer to Capability section of this page for more details.